TECHNOLOGY

Micropulva Ltd Oy: R&D

Micropulva has over 30 years of experience in micronizing technology and its applications. Micronizing equipment is delivered not only to Finland but also around the world. Applications include milling sugar, cocoa, wheat, ilmenite, wollastonite, platinum furnace matte, to name a few.

The key personnel have long experience in the mining, minerals and chemical industries, construction materials, pulp and paper and energy production, finance and administration.

Micropulva has a patent portfolio that covers the key technologies and applications based on the patents.

Micronization

Effective and economical micronization is based on two-phase flow utilizing the law of kinetic energy E=mv2/2.

Cost-effective production of particle surface area m2/kWh:

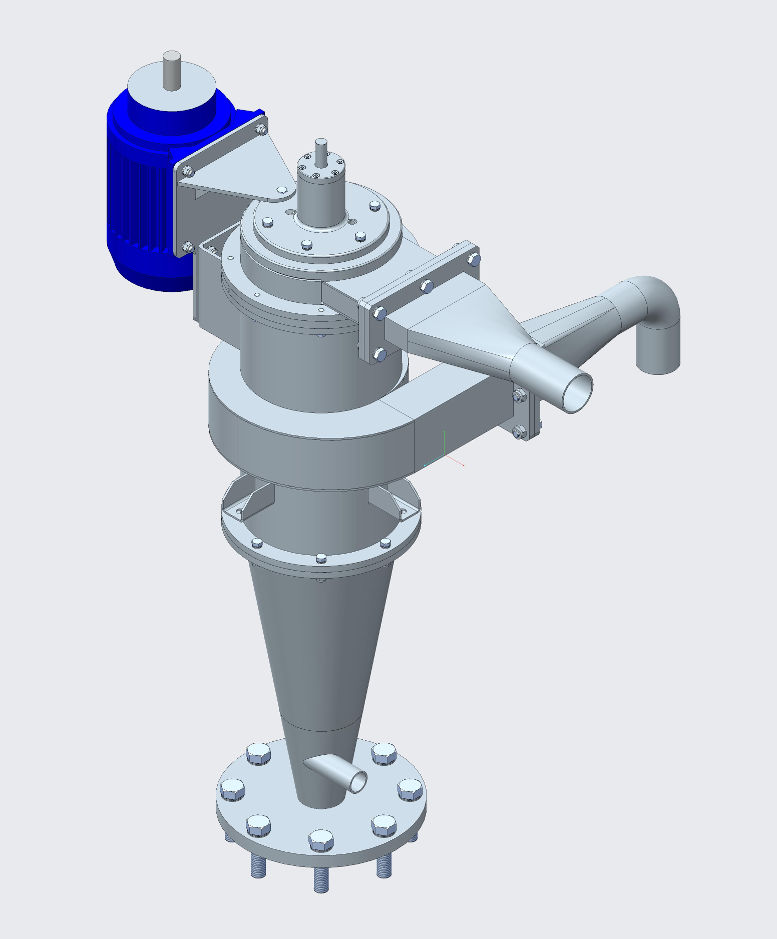

Microclassification

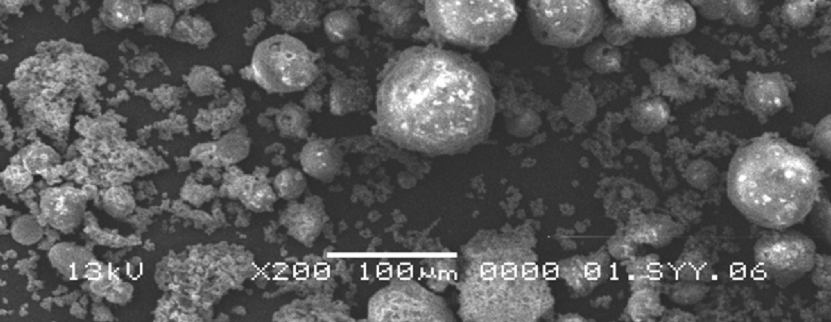

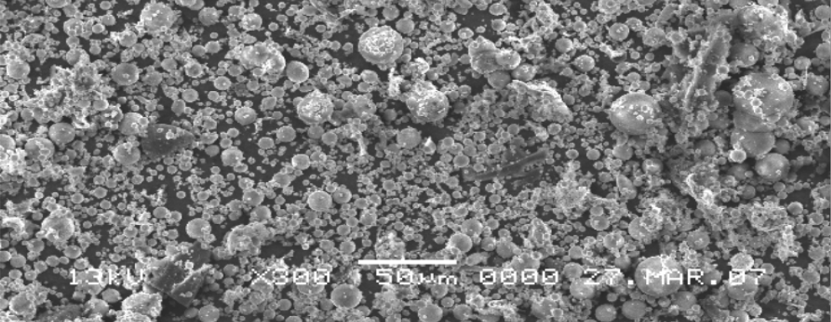

Carbon-free fly ash

Carbon-free fly ash can be used in concrete, significantly reducing the use of cement and enhancing sustainable development by reducing the use of non-renewable raw materials and by lessening the carbon footprint in the cement and construction industries.

The end products are nearly carbon free, reactive mineral fraction and carbon concentrate, which can be used in further processing.

The most effective mineral and coal separation method is the well-known flotation method.

Closed water process, no environmental risks.

Old, huge fly ash deposits can be economically recycled for reuse.

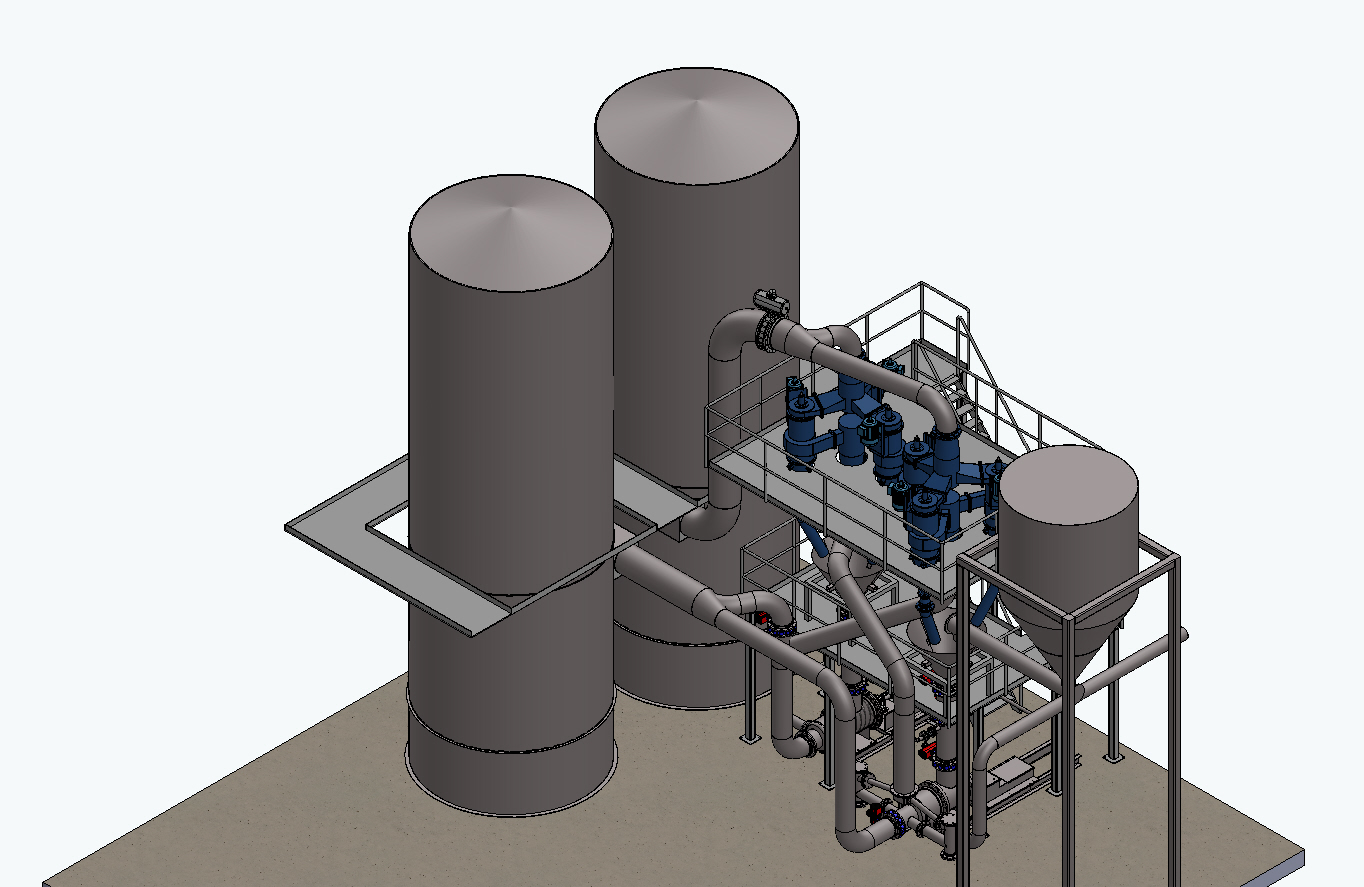

Micropulva piloting and testing

Customer raw material testing and mutual acceptance of the test results is vital for successful equipment delivery. Micropulva has a modern, state-of-the-art piloting and testing facility that assesses feasibility, end product quality and cost economy.

The pilot equipment can be operated in either micronizing or microclassification mode.

A comprehensive report with particle size distribution curves of the material before and after testing is provided.

Pulva FP2 pilot plant

Open video page here. Start video by clicking the picture.