MICROPULVA TECHNOLOGY BENEFITS

Uniform quality of the product with controlled particle size distribution. Even nanosize products are economically feasible. Competitive Capex and Opex. Short payback period.

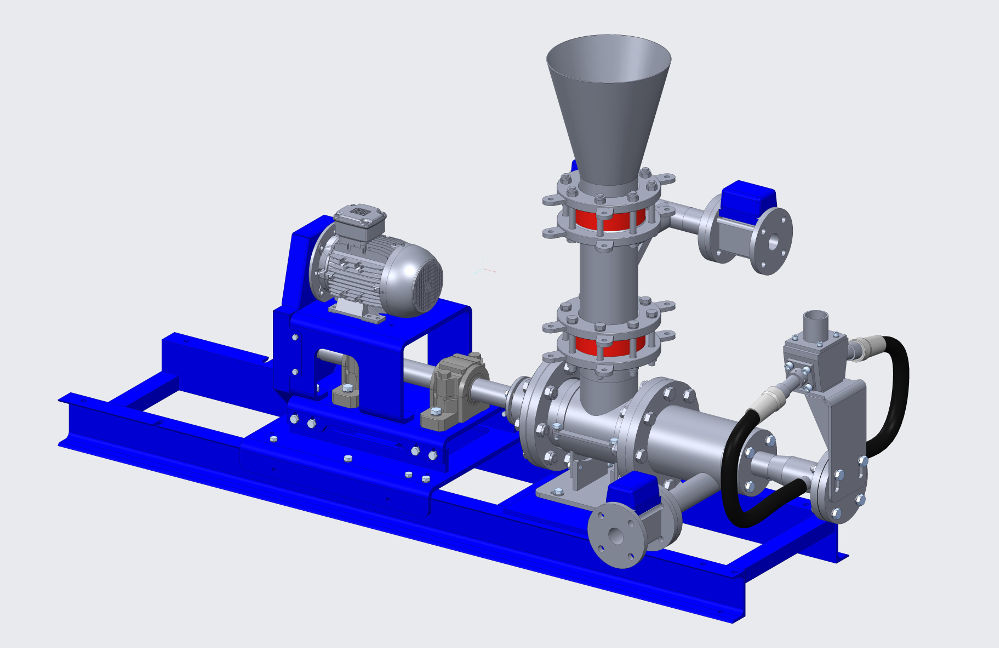

Small footprint

Simple construction, versatile process: dries – mills – classifies

Simple installation

No waste heat

Low noise level

Low operating cost:

Up to 50% less energy per unit of final product compared to the competitors.

Can replace some mechanical milling processes due to low energy consumption.

Low Opex, no wearing parts

Micropulva: Economy

The technology facilitates the production of new products, even from raw materials that have been difficult to produce.

Enhancement of product quality by optimization of the particle size distribution.

The micronization and classification technology is extremely energy-efficient compared to competing technologies.

Can be delivered in modules.

The applications are designed together with the client to meet the requirements of each specific application.

Micropulva: Ecology

Saving of non-renewable natural resources

MINERALS

Dry concentration

OTHER APPLICATIONS

Chemical products

Foodstuff

Sustainable development

INDUSTRIAL SLAG

Metals recovery

Binder for cement and concrete

INDUSTRIAL ASH

Clinker replacement in cement

Forest fertilizer and binder